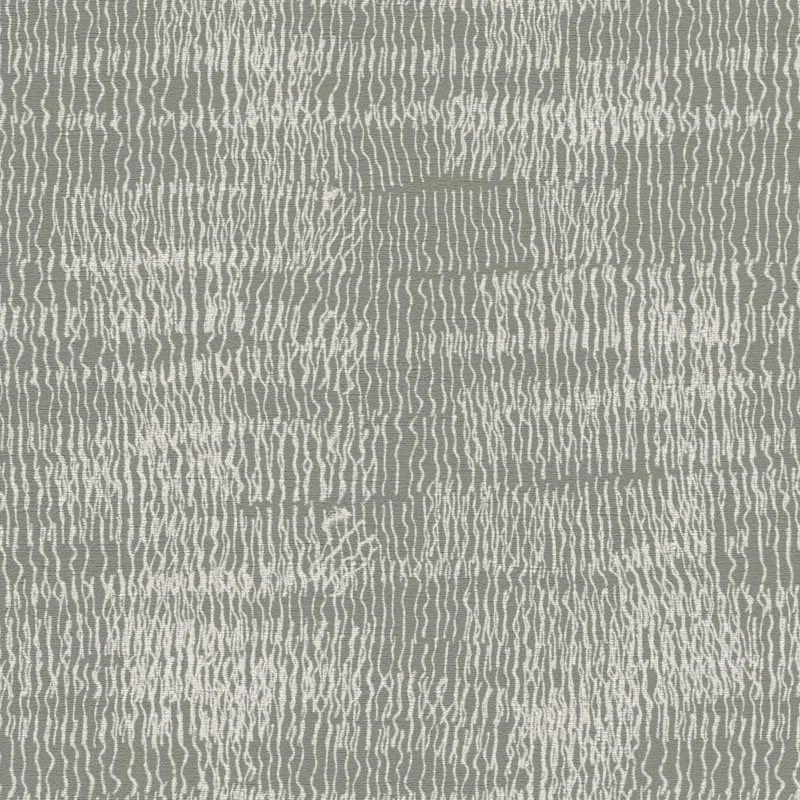

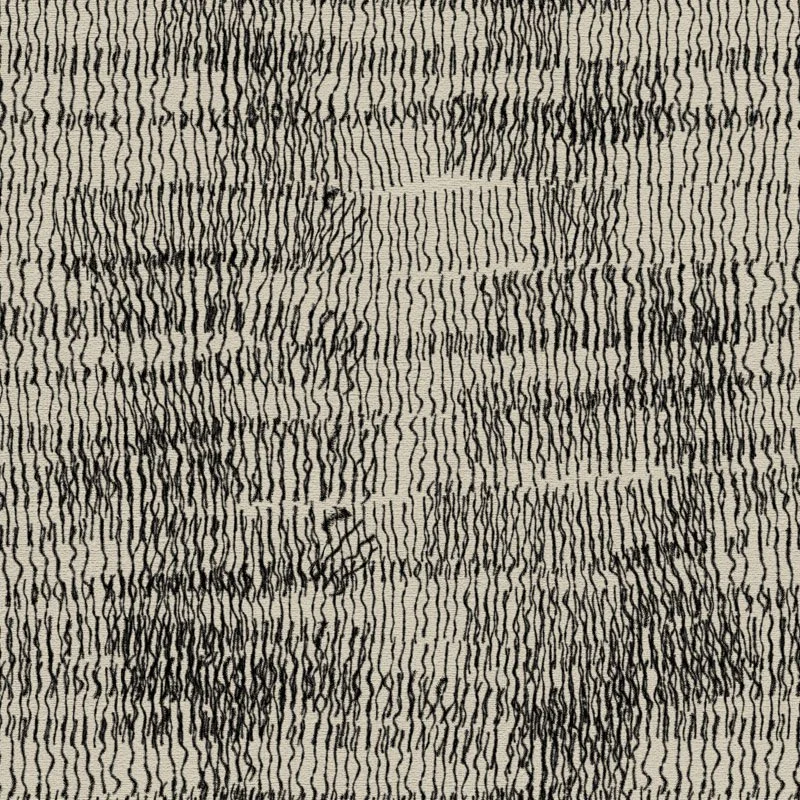

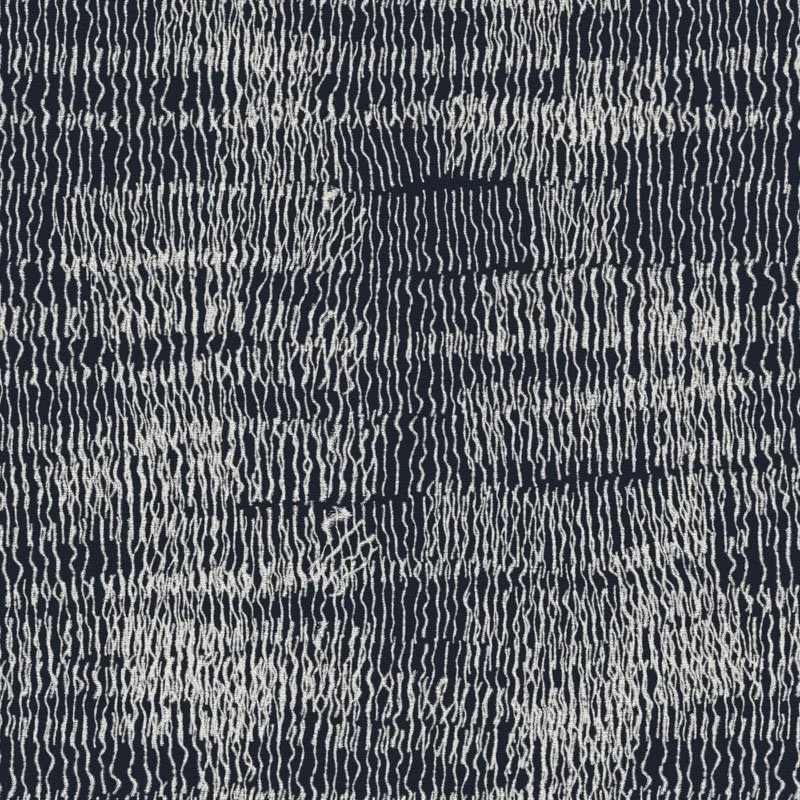

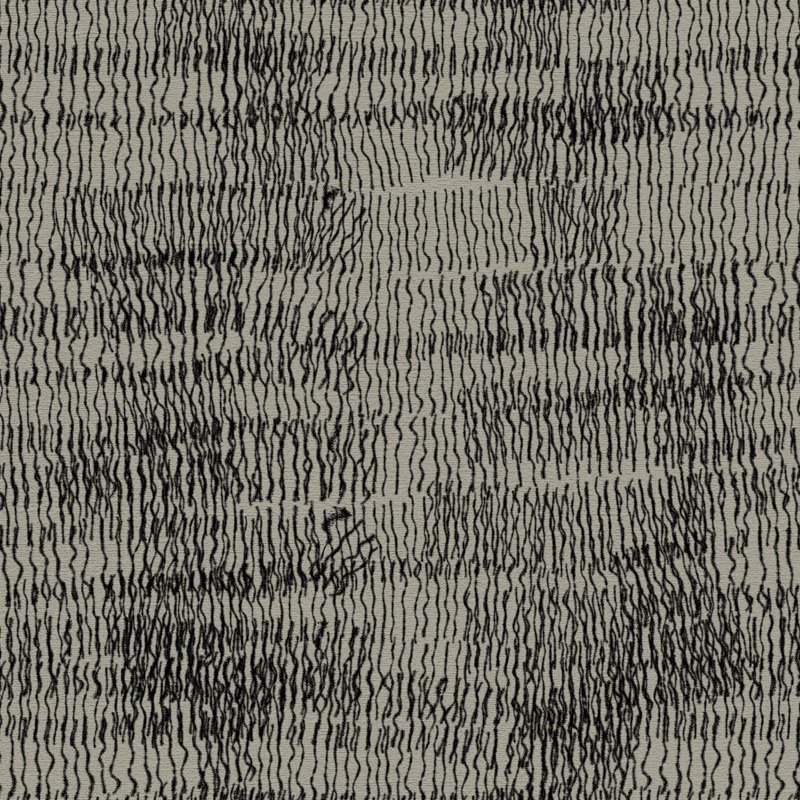

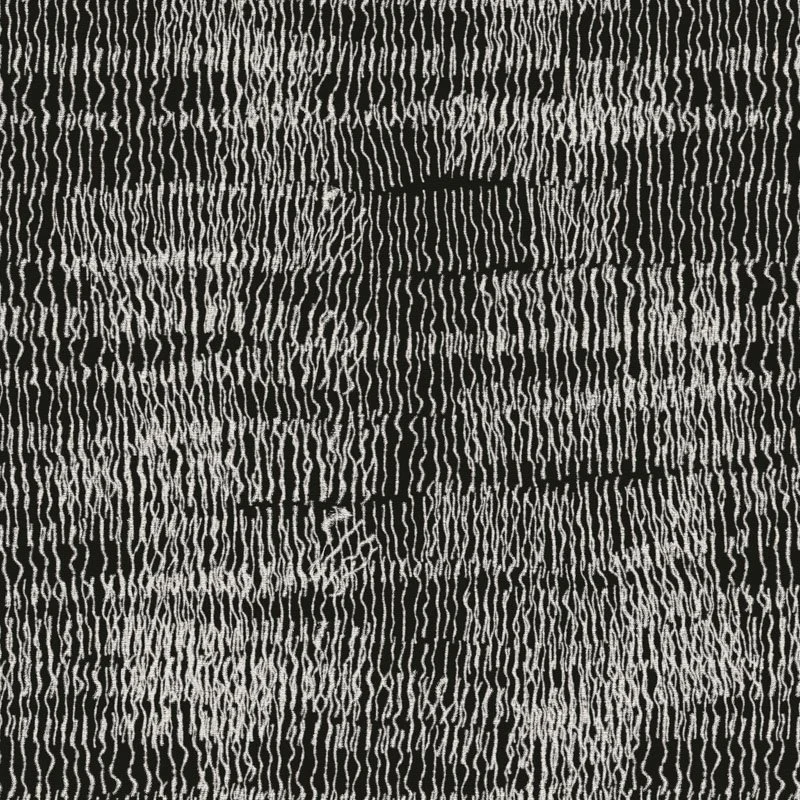

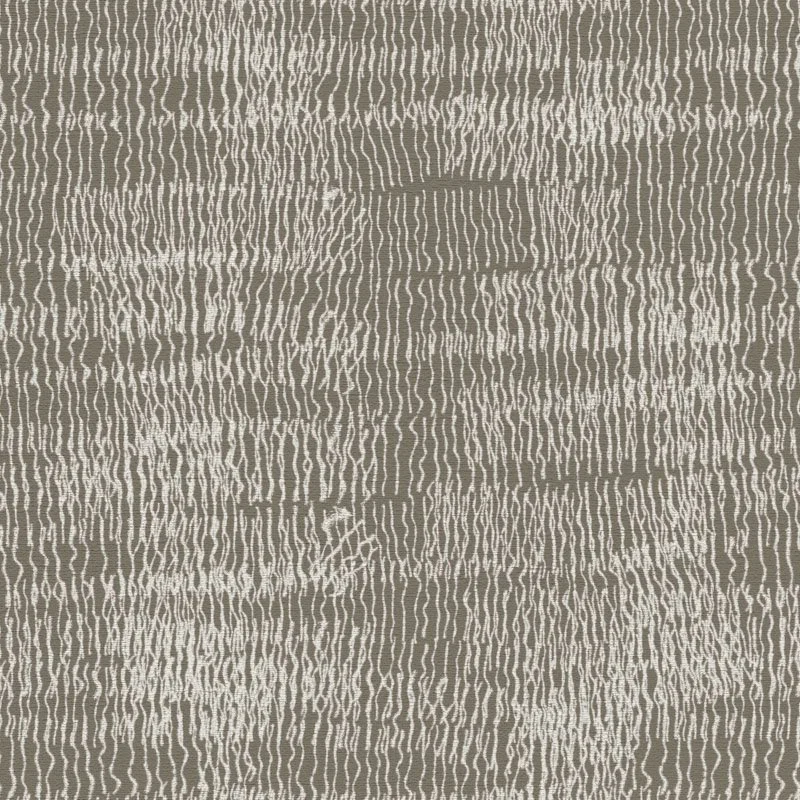

Static

DETAILS

GRANDE SCALE: 26" repeat (2 repeats per roll width)

TITIAN SCALE: 52" repeat (1 repeat per roll width)

Category V, WA-101, Type II Vinyl

Backing: Woven

Roll Width: 52 in. (132cm)

52 inches wide × 11 yards long (covers 143 square feet)

Weight: 20oz lyd

Made in USA, 2-4 week lead time

Available in PVC Free, Waterproof & Microvent substrates for an extra fee

-

Tensile (Minimum): 50 x 55 lb1 (222 x 245 N)

Tear (Minimum): 25 x 25 I b1 ( l l l x l l l N)

Federal Spec: CCC-W-408D, Type II

WA Spec: WA-101, Type II

ASTM F-793: Category V, Type II

Fire Testing:

N FPA l0l ® Life Safety Code®

NFPA 255 (ASTM E-84, CAN S l 02M) Tunnel Test (1)

- Class A Rating

- Flame Spread - l0

- Smoke Developed - 5

NFPA 286 Corner Burn Test (2)

- Meets requirements for Flame Spread, Smoke Developed, & Flashover

(l) When applied to GRC board with A-848-B adhesive (2) When applied to 5/8" Type-X-Gypsum board with A-848-B adhesive

CE Certification: EU classification in accordance with EN 15102:2007 +Al :2011

Indoor Air Quality: California 0 1350- Meets emission requirements for schools and offices -

READ BEFORE USING

If you have any questions about the proper installation of this product, please call your Distributor or contact your Sales Representative before processing.PREPARATION OF GOODS

Examine goods to assure that pattern, color, quantity and quality are as ordered. Separate goods by shade lot number and organize in roll number sequence.PREPARATION OF SURFACE

Surfaces to be covered must be clean, smooth, dry and structurally sound. Loose paint or other wallcoverings must be removed. In order to ensure maximum smoothness of installation, nail heads, nicks, gouges and other surface imperfections should be filled, sanded smooth and sealed. On new walls, drywall joints should be taped, bedded and sanded smooth.Mold and mildew require moisture in order to grow; therefore it is important to check the walls with a suitable moisture meter. Moisture content should not exceed 4%. Excessive moisture in wall needs to be corrected prior to installation of the wallcovering. Remove any mold and mildew from existing wall and treat surfaces to inhibit future growth.

Wallcovering can be installed over almost any surface that has been properly prepared. Do not hang vinyl over ballpoint pen markings, wax crayon, ink marker, oil-based stains or any foreign matter that may bleed through the vinyl. Painted surfaces should be checked for possibility of pigment bleed-through. It is suggested that lead pencil be used to mark vinyl or wall. Glossy surfaces should either be sanded to dull surface or an application of professional R-35 heavy-duty primer.

A primer must be used, if there is a desire for possible future stripping. Some drywall joint compounds contrast with the drywall paper surface, showing strong light and dark colored areas. Very lightly colored, light-weight wallcoverings may seem shear due to their limited amount of opacity. Should this situation occur, we recommend that you use a primer followed by Koroseal Heavy Duty A-848-B adhesive or an equivalent commercial grade wallcovering paste.

APPLICATION OF WALLCOVERING

Before hanging, examine panels for color uniformity and consistency of design. Follow instructions packaged with the roll. All material must be installed sequentially.Graphic design of panels will determine seaming method to be implemented. Overlapping, double-cutting and pre-trimming have advantages in making acceptable seams. Do not “score” drywall when double-cutting.

As with all vinyl wallcoverings, certain deeply embossed non-design print patterns will provided a more satisfactory seam if through the graphic design a two – three inch selvage cut can be taken from each side of the sheet. When hanging materials it is best to observe from a distance the first two – three sheets before continuing. It is “unacceptable” edge is visible, contact your distributor.

Apply an even coat of adhesive of fabric side of material using a stiff bristle brush, roller or pasting machine in accordance with label recommendations. The wallcovering should be applied to the wall as soon as it has become tacky. Smooth surface, while working out the air bubbles as you go. As each strip is installed, immediately remove excess adhesive from wallcovering surface and seam using a natural sponge and a soft bristle brush frequently rinsed it in warm water and dry with a clean cotton towel. Use a professional vinyl cleaner/wallpaper remover where adhesive products have been specifically developed for use in these applications. We are not responsible for the appearance and performance of the wallcoverings not applied according to these instructions.

Vertical joins should not occur less than 6 inches from outside or inside corners.

Do not install wallcoverings unless a temperature above 55oF is maintained in both areas of installation and storage. Permanent building lights should be available for installation.

After applying three strips, if there are any questions or comments of appearance, stop and contact your distributor.

IMPORTANT: No claims will be accepted after installation.

-

Stains should be removed as quickly as possible to eliminate any possible reaction between the staining agent and the wallcovering. Time is especially important for removing materials containing colors or solvents such as ball point ink, nail polish, lipstick, oil shampoo tints, paint, lacquer or enamel and some foods.

The normal cleaning of the wallcoverings should be done with mild ingredients such as soap, detergent and water. If stained and stronger cleaning is required, a liquid household cleaner should be used. Liquid cleaners should be of low VOC content and non-abrasive.

Metallic finishes can be discolored with the use of caustic cleaners. Thus, we recommend only the use of a mild soap solution for cleaning these products. If stronger cleaning is required, first evaluate the cleaner in an inconspicuous location.

The method of cleaning should be to use a natural sponge and mild soap solution. A natural sponge’s construction does the best job of removing dirt from the textured surface. With difficult to remove deposits, the use of a soft bristle brush is recommended. Then, rinse thoroughly with clean clear water, changing the water often to insure it remains clean and clear. After cleaning an area, be sure to dry with an absorbent cloth so it can be examined to assure complete cleaning.

NEVER MIX CLEANING AGENTS TOGETHER. VIOLENT REACTIONS MAY OCCUR WHICH COULD RESULT IN SERIOUS INJURY. OBSERVE ALL LABEL PRECAUTIONS WHEN USING THESE AND ANY CLEANING AGENTS.

Repeated use of stronger cleaners will extract plasticizer from vinyl wallcoverings causing the wallcovering to lose its suppleness.

PRECAUTIONS: Excess soiling materials such as chewing gum, asphalt, crayon, paint, nail polish or tar should be carefully scraped off prior to other cleaning attempts.